QuACX:smartLCC

QuACX:smartLCC connects chromatography data systems (CDS) with LabX® from Mettler Toledo.

Read about the advantages this interface offers you, both in economic terms and with regard to your position vis-à-vis the supervisory authorities.

As part of chromatographic analysis, it is always necessary to prepare the samples to be analyzed using defined processes.

A range of software-supported laboratory devices such as precision trolleys, titrators or automatic dosing systems are often used for this purpose, such as the devices from Mettler Toledo with their LabX® system.

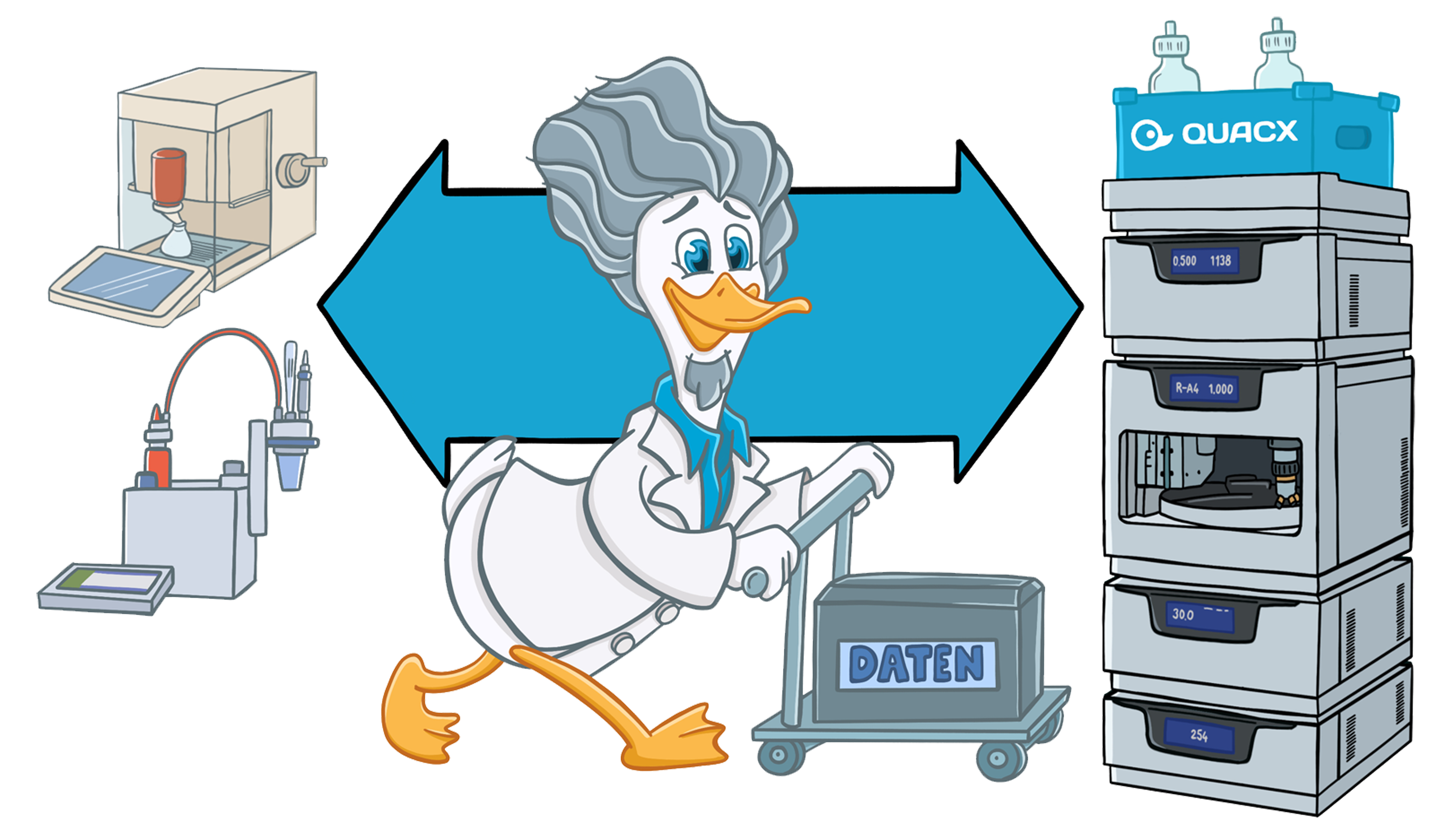

The typical workflow consists of first defining the necessary samples (aka injections) in sequences in a chromatography data system (CDS) such as Chromeleon™ from Thermo Fisher Scientific.

From these sample definitions, tasks and samples have to be defined manually in LabX® and the key figures transferred by hand.

In the laboratory, the tasks that have just been created are now processed with workflow support and the samples are generated.

For the calculations in the CDS, it is essential to know the exact values (i.e. the actual values), which is why the measurement results from the sample production, which are recorded and saved by LabX®, must be manually transferred back to the CDS.

In a regulated environment, this is further complicated by the obligation to retain the leaflets and the unspoken suspicion of deliberate manipulation that is always present on the part of the supervisory authorities.

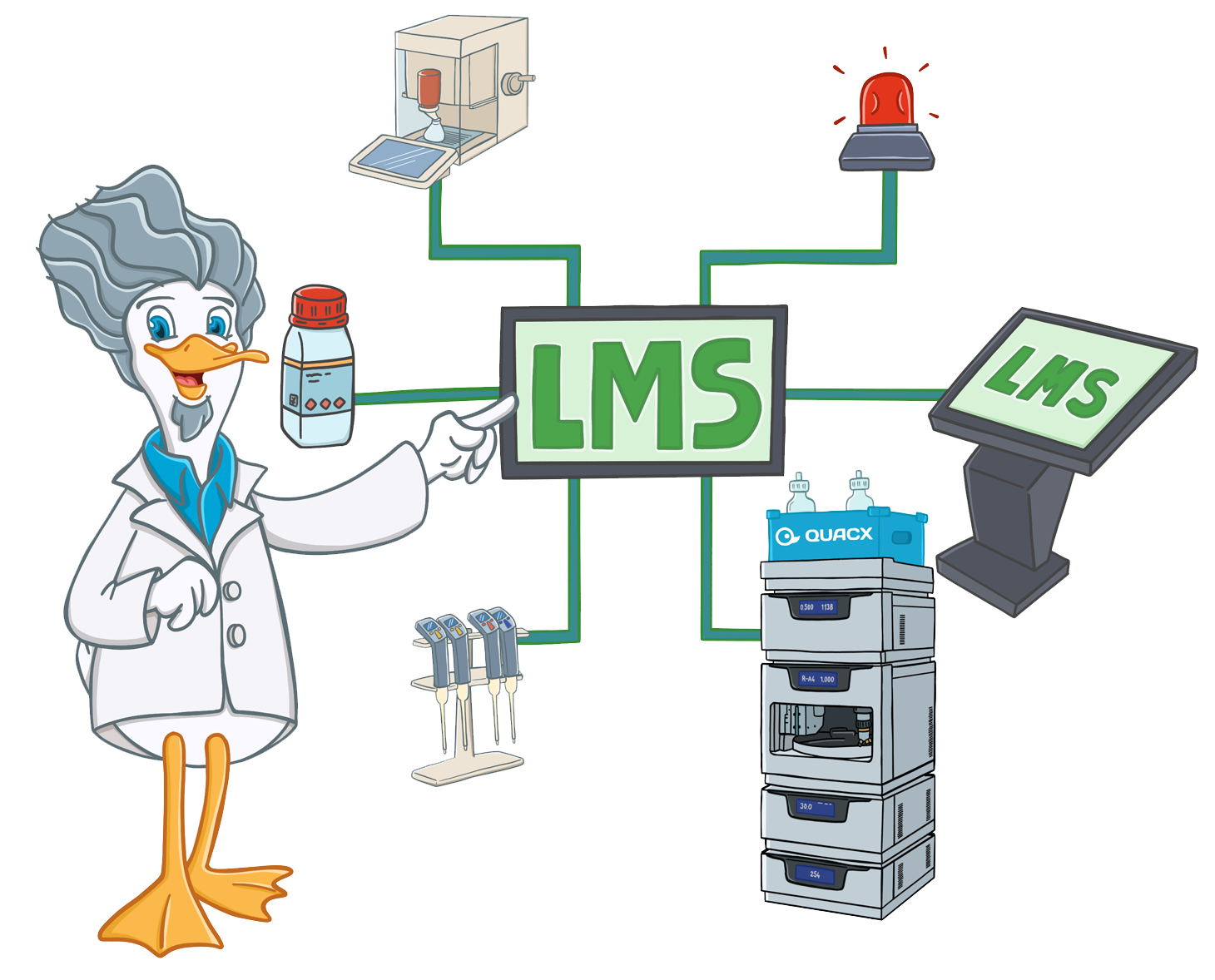

QuACX:smartLCC links the CDS with the LabX® software in such a way that sample definitions created in the CDS (both injections and entries from component tables) are transferred electronically to LabX® and the tasks are correctly created there in the form of tasks and samples.

The user is completely free to select the data to be transferred, define the workflow in the form of the LabX® method and select the desired laboratory device and laboratory technician.

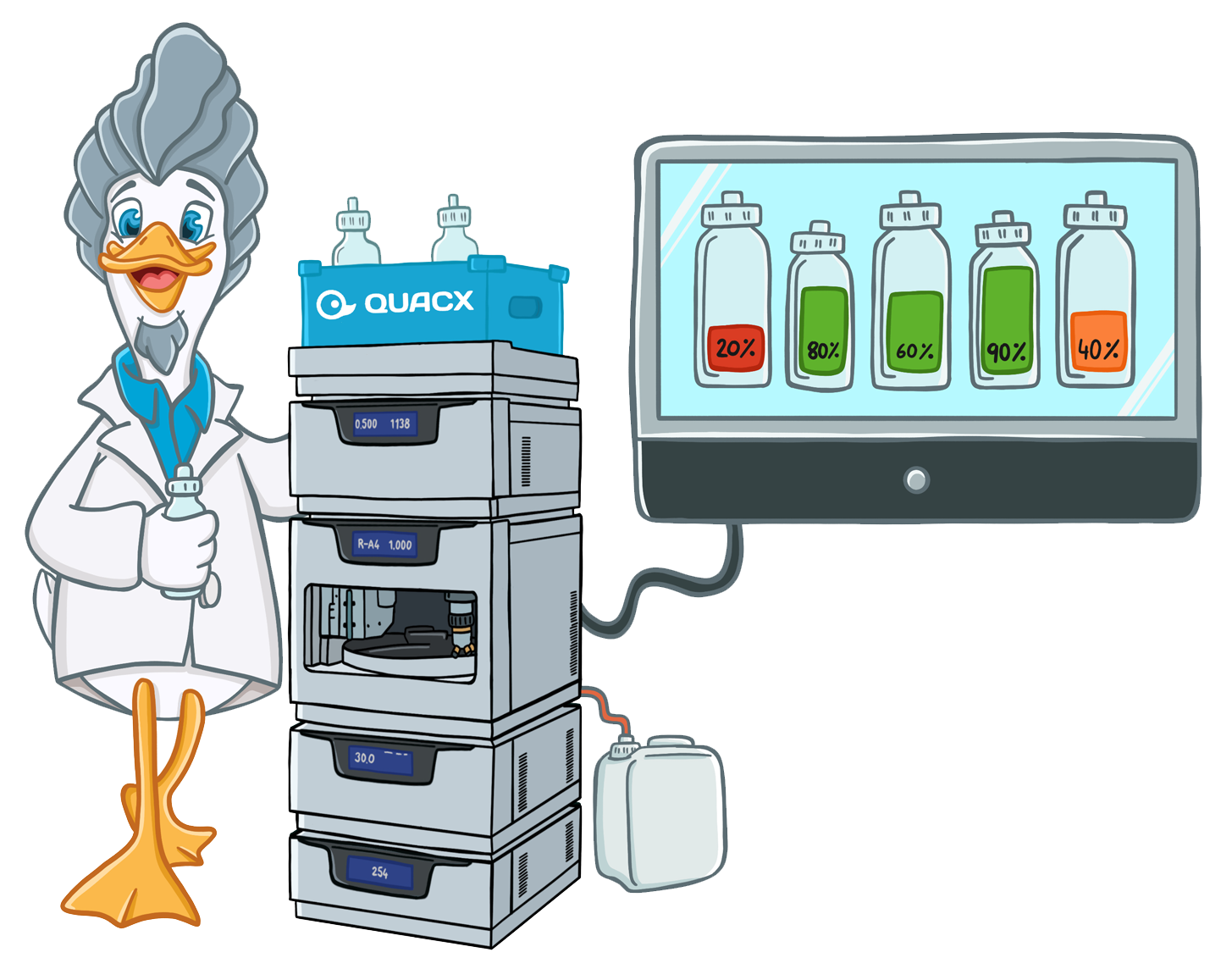

Once the samples have been produced in the laboratory, the measured values recorded during the production process, such as weights, can be called up from the CDS in LabX® and entered in the correct injections or rows of the component table.

Transcription errors such as slips in the line, transposed digits, etc. are completely eliminated, manual effort is reduced to an absolute minimum, which saves valuable and expensive working time and speeds up the processes overall.

Thanks to end-to-end electronic communication, there is no longer any obligation to store paper files and the silent accusations of the supervisory authorities can be met with a clear conscience, as the wind has been completely taken out of their sails.

Contact us now

Are you interested or do you have questions about our products? Get in touch with us now using our form.